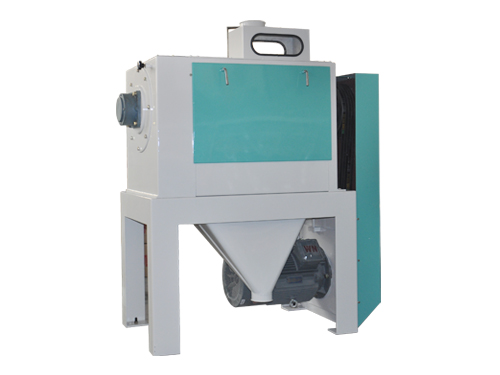

Explain:

It is a kind of equipment with double functions - wheat grinding & scouring, which is designed by combining with the characteristics of wheat scourers produced at home and abroad, as well as the actual conditions of domestic wheat and processing. It is used in the cleaning process in flour mill, which can knead and remove the soils, wheat furs and other impurities on wheat surfaces and stuck in ventral grooves; besides, it can also smash the clod and diseased wheat with low strength which are mixed in wheat. The smashed soils and fine impurities are discharged via air suction system.

Characteristics:

1.Grinding & scouring processes are adopted for the equipment, improving the wheat cleaning effect

2.The breaking rate is lower than that of traditional wheat scourers

3.Dynamic balance test has been conducted for the equipment, and it can operate steadily, with low noise

4.It is featured with satisfactory sealing effect; it is under negative pressure during operation; and no flying dust is found

Process parameters:

|

Name |

FDMM series friction wheat scourer |

|

Removal efficiency of mixed impurities |

≥80% |

|

Ash powder rate |

≥0.09% |

|

Increasing rate of creaked wheat |

≤0.04% |

Technical parameters:

|

Spec. & model |

Drum diameter (mm) |

Drum length (mm) |

Speed (r/min) |

Output (t/h) |

Power (kw) |

Mass (kg) |

Boundary dimension (L × W × H) |

|

FDMM30×60A |

300 |

600 |

650~780 |

≤12 |

7.5~15 |

760 |

1220×600×1615 |

|

FDMM45×80A |

450 |

800 |

437~550 |

12~22 |

15~22 |

1100 |

1542×850×1880 |